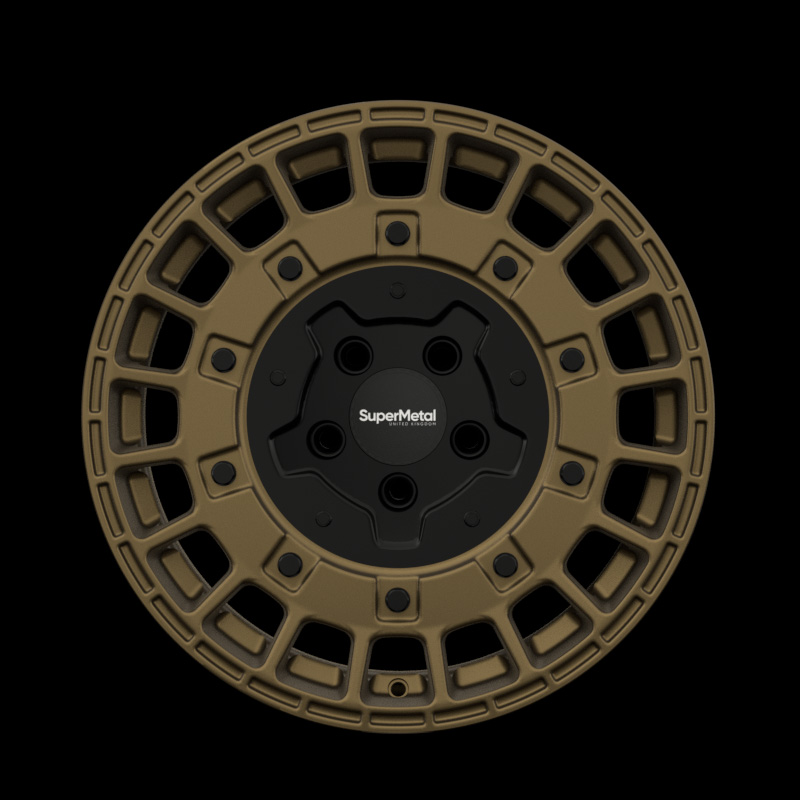

The SuperMetal Rig

The Rig is a strong and durable wheel. Made from the highest grade Aluminium alloy composition and given the most extensive heat treatment, the Rig is as superior on its inside as it is on the outside. The Rig is all about utility, designed and refined in its contours and patterns to resonate its nomadic purpose. Fine detailing and exposed bolt heads add to the authenticity of its duty. Rig is our first multi-colour painted wheel, achieved with an extra process in the paint shop that we call Smart Masking. This process applies two separately painted colour variations on one wheel, with precision seamless edges.

Sizes + Specifications

| RIM SIZE | PCD | OFFSET | CENTRE BORE |

|---|---|---|---|

| 6.5 x 16″ | 6/120 | ET 50 | 74.6 FIXED ECE |

| 6.5 x 16″ | 6/130 | ET 50 | 84.1 FIXED ECE |

| 7.5 x 17″ | 5/112 | ET 42 | 66.6 |

| 7.5 x 17″ | 5/118 | ET 55 | 71.1 FIXED |

| 7.5 x 17″ | 5/120 | ET 48 | 65.1 FIXED |

| 7.5 x 17″ | 5/130 | ET 55 | 78.1 FIXED |

| 7.5 x 17″ | 5/160 | ET 50 | 65.1 FIXED |

| 7.5 x 17″” | 6/120 | ET 48 | 74.6 FIXED |

| 7.5 x 17″” | 6/130 | ET 55 | 84.1 FIXED |

| 8.0 x 18″ | 5/120 | ET 40 | 65.1 FIXED |

| 8.0 x 18″ | 5/160 | ET 45 | 65.1 FIXED |

| 8.0 x 18″ | 6/120 | ET 45 | 74.6 FIXED |

Colours + Finishes

CLICK & DRAG WHEEL TO ROTATE

TOUCH & SWIPE WHEEL TO ROTATE

Video

The SuperMetal Warranty

The SuperMetal Warranty gives a reassuring two years peace of mind.

We continually develop our clear coats to improve the barrier between the wheel and the outside elements whilst maximising the aesthetic effect of the clear coat finish. Our latest V4.0 clear coat is a dry lacquer formula which is applied by charging the wheel and attracting the lacquer particles to the painted or polished surface, this process ensures an even and consistent solid coating.

The structure of a SuperMetal wheel is it’s most important feature, with some wheels capable of extremely high loads. Working to TUV standard ensures the engineered load from the start, passing the most robust TUV tests in the world: Rim Rolling, Bending Fatigue and Impact Test. Every wheel we form is X-rayed on the production line, this technology scrutinises the material integrity and ensures structural conformity before the wheel moves on to it’s T6 level heat treatment.