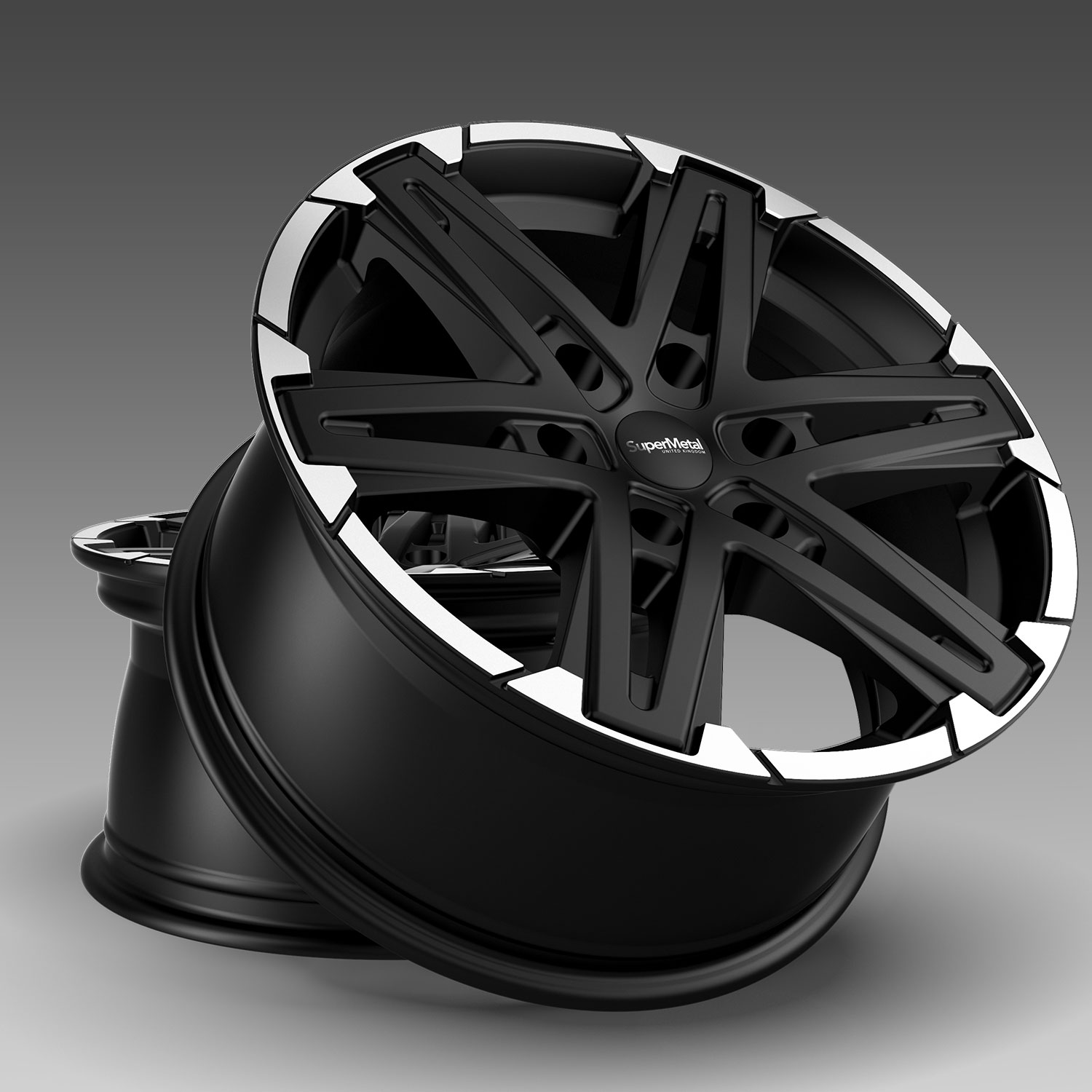

The SuperMetal Compass

The Compass is produced in 8.5″ x 18″ for off-road applications such as pickup models and transporter T5 and T6. The Compass is an extremely tough wheel enduring the most rigorous TÜV testing to achieve an approved load of 1050kg per wheel. The robust design truly encompasses the off-road style with core SuperMetal design features meaning that the Compass is used by OEMs in Europe.

Colours + Finishes

CLICK & DRAG WHEEL TO ROTATE

TOUCH & SWIPE WHEEL TO ROTATE

Vehicle Fitment

| Manufacturer | Model | Type |

|---|---|---|

| Volkswagen | VW Amarok | 2H, 2HS2 |

| Volkswagen | VW Bus (T5) | 7HC, 7HCA, 7HK. |

| Volkswagen | VW Bus (T5) | 7HM, 7HMA |

| Volkswagen | VW Bus (T5) | 7J0 |

| Ford | Ford Ranger | 2AB |

| Mercedes | Mercedes X-Class | 4701 |

| Mitsubishi | Mitsubishi L200 | KJ0T |

| Mitsubishi | Mitsubishi Pajero | V80, V8V |

| Toyota | Toyota Hilux Pickup | AN1P, AN1P-TMG |

| Toyota | Toyota Hilux Pickup | N2 |

| Nissan | Nissan NP300 Navara | D231 |

| Renault | Renault Alaskan | D231C |

Video

The SuperMetal Warranty

The SuperMetal Warranty gives a reassuring two years peace of mind.

We continually develop our clear coats to improve the barrier between the wheel and the outside elements whilst maximising the aesthetic effect of the clear coat finish. Our latest V4.0 clear coat is a dry lacquer formula which is applied by charging the wheel and attracting the lacquer particles to the painted or polished surface, this process ensures an even and consistent solid coating.

The structure of a SuperMetal wheel is it’s most important feature, with some wheels capable of extremely high loads. Working to TUV standard ensures the engineered load from the start, passing the most robust TUV tests in the world: Rim Rolling, Bending Fatigue and Impact Test. Every wheel we form is X-rayed on the production line, this technology scrutinises the material integrity and ensures structural conformity before the wheel moves on to it’s T6 level heat treatment.